Understanding CMMS software and its role in maintenance management

We are living in a time where longevity of assets is important. Hence an effective maintenance management is essential for ensuring operational efficiency and improving uptime. Maintenance and upkeep of assets, is an integral core function of facilities management. It can’t be said enough that facilities management is always mistaken as maintenance or maintenance equals to facilities management, due to the close relationship for both.

Computerised Maintenance Management Systems (CMMS) are crucial tools that help organisations manage their maintenance operations across various sectors. Although we have debated in our previous article about cross functioning software, that it should not limited to one, if it can served more. Let’s talk about that more soon.

This article will explore the role that CMMS plays, particularly on maintenance management, current practices, challenges in the field and how to enhance maintenance management.

What is CMMS software?

CMMS is a software to streamline the organisation’s maintenance tasks. It’s a legacy software that goes way back to 1960’s. It automates work order management, monitors asset health, schedules preventive maintenance, and tracks inventory.

CMMS originated in the 1960s as simple punch-card and early computer-based systems designed to track maintenance tasks in industries such as manufacturing and utilities. With advancements in computing technology during the 1980s and 1990s, CMMS evolved into more sophisticated database-driven applications, enabling better scheduling, asset tracking, and reporting.

The rise of the internet and cloud computing in the 2000s further transformed CMMS, making it accessible from anywhere and integrating it with other enterprise systems such as ERP and IoT. Today, CMMS is widely used in property and facilities management to optimise asset performance, reduce downtime, and ensure regulatory compliance through data-driven maintenance strategies.

The core functions of CMMS include:

- Work Order Management: Creating, assigning, and tracking work orders.

- Locations Management: Location registry, the main hierarchy of assets management starts with accurate location registration

- Asset Management: Monitoring asset performance and history.

- Preventive Maintenance: Scheduling regular maintenance tasks to prevent equipment failures.

- Inventory Management: Keeping track of spare parts and supplies.

- Reporting and Analytics: Generating insights to improve maintenance strategies.

So, if you’re starting your journey to choose your CMMS, you need to ensure these features are available as a minimum. It will help your organisation enhance productivity, reducing unnecessary costs, and extend the lifespan of their assets.

If not, you will be missing the crucial piece of automated workflow needed for you to benefit from the software.

The importance of maintenance management

Effective maintenance management is essential for various sectors including manufacturing, healthcare, hospitality, and energy. Each industry has unique requirements but shares common goals:

- Manufacturing: Reducing unscheduled downtime to maintain production efficiency.

- Healthcare: Ensuring equipment reliability for patient safety.

- Hospitality: Enhancing guest satisfaction through well-maintained facilities.

- Energy & Utilities: Maintaining critical infrastructure to prevent service disruptions.

The common goal of maintenance is to ensure zero or minimum interruptions to business operations. The more critical the industry (healthcare, banking, data-center, etc.), the higher the priority of getting the operation uptime to almost 100%. Usually the maintenance team for this industry is always put to a higher and stringent standards.

Current situation of maintenance management practices

Despite advancements in technology, many organisations still rely on outdated maintenance practices that can lead to inefficiencies. Common issues include:

- Lack of real-time data on asset performance.

- Inefficient scheduling of maintenance tasks.

- Inadequate tracking of work orders and inventory.

- Difficulty in complying with regulatory standards.

These challenges highlight the need for a more systematic approach to maintenance management that can adapt to evolving industry demands.

Issues needing change in current maintenance management

Several key issues in current maintenance practices require urgent attention:

- Reactive Maintenance: Many organisations still operate on a reactive basis, addressing issues only after they arise. This approach can lead to increased downtime and higher repair costs.

- Data Silos: Information about assets is often scattered across different systems or departments, making it difficult to access crucial data when needed.

- Manual Processes: Reliance on paper-based systems or spreadsheets can slow down operations and increase the chances of errors.

- Compliance Challenges: Ensuring compliance with safety and regulatory standards can be cumbersome without a centralised system for tracking maintenance activities.

Solutions for effective maintenance management

To address these challenges, organisations should consider implementing a robust CMMS or any suitable integrated system. The software features should tailored for effective maintenance management:

- Automated Work Orders: Streamline task assignments and tracking.

- Real-Time Asset Monitoring: Gain insights into asset performance with real-time data.

- Preventive Maintenance Scheduling: Reduce downtime through proactive maintenance strategies.

- Integrated Reporting Tools: Analyze data for informed decision-making.

By adopting a robust CMMS, organisations can significantly improve their maintenance practices, leading to enhanced operational efficiency and reduced costs.

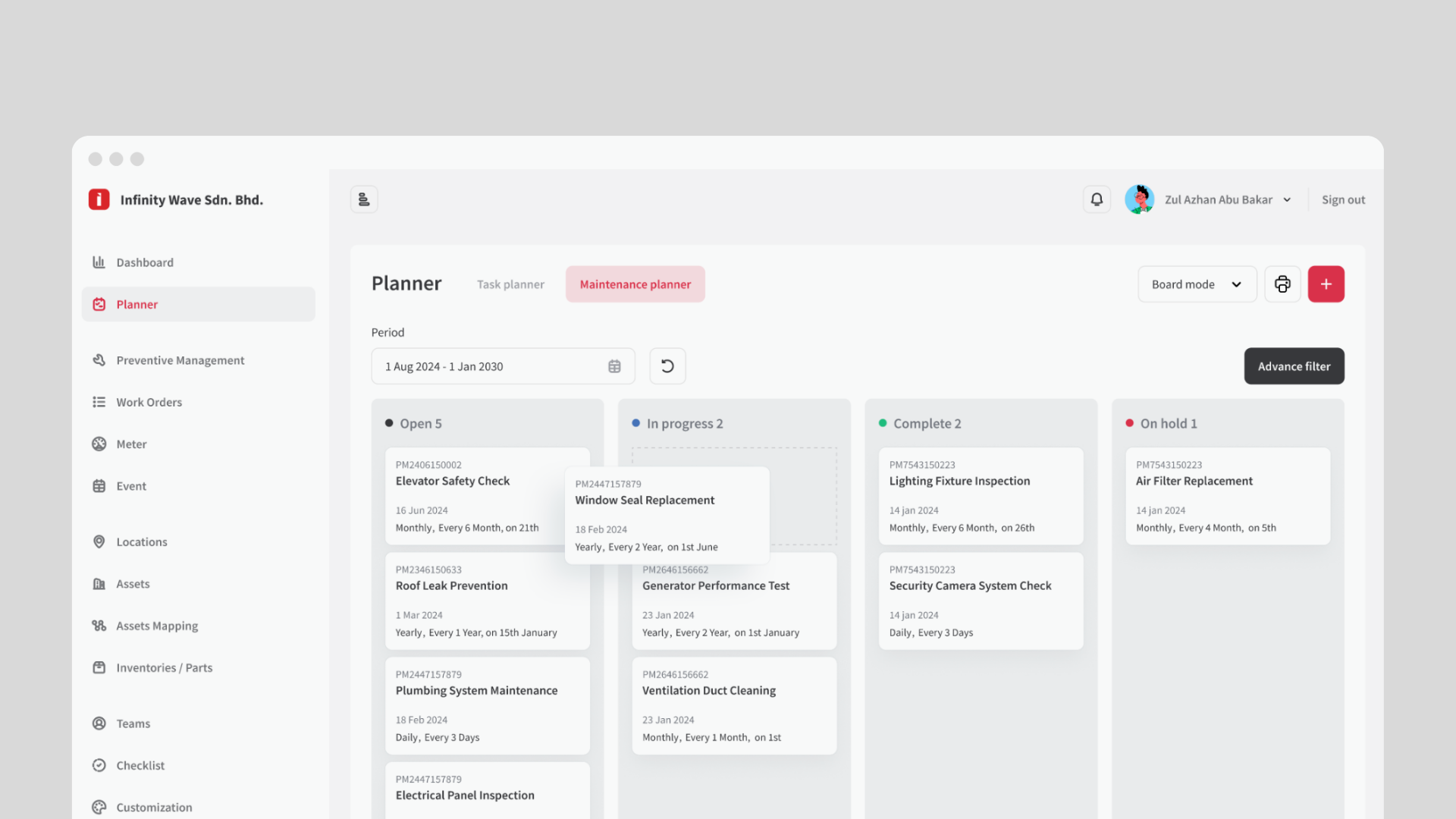

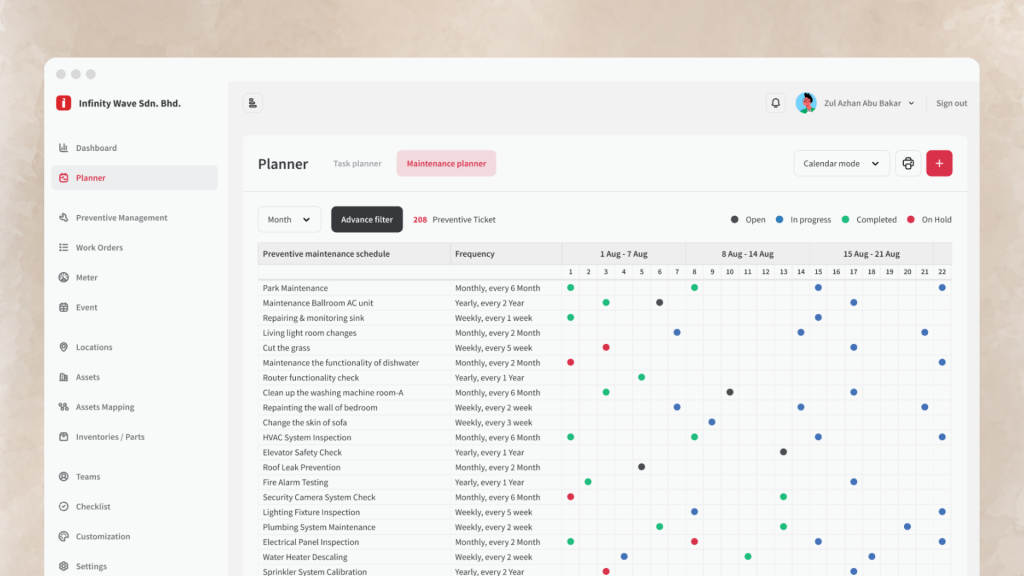

FOX by Infinity Wave gave a unified visualisation of your preventive plans and intuitive designs make it easier to navigate and make informed decision.

Conclusion

In conclusion, CMMS software is vital for modern maintenance management across various industries. As organisations face increasing pressure to optimise their operations, transitioning from outdated practices to a comprehensive system can provide significant advantages. By leveraging advanced features that streamline processes and enhance data accessibility, companies can ensure better asset management and compliance while reducing downtime and costs.

At Infinity Wave, we specialise in delivering advanced solutions like FOX, designed to revolutionise facility management. Whether you’re looking for the flexibility of a cloud-based system or the control of an on-premise solution, we can guide you toward the best fit for your business.

Learn how FOX can optimise your maintenance processes and improve operational efficiency. Explore our solutions to take your facility management to the next level.